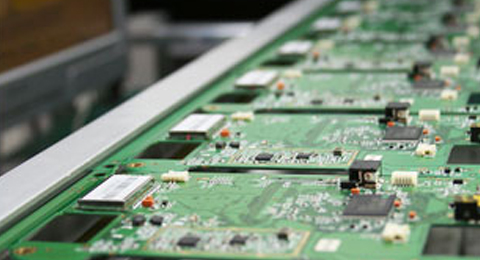

PCBA plate welding will produce pores, which is often referred to as bubbles. Stomata usually appear in reflow welding and wave soldering, too many stomata will lead to damage to PCB board, so today xiaobian will bring you a way to prevent PCBA processing welding from producing stomata.

1, baking

Bake PCB and components exposed to air for a long time to prevent moisture.

2. Control of solder paste

Tin paste containing moisture is also easy to produce pores, tin beads. First of all, choose good quality solder paste. The temperature return and stirring of the solder paste are strictly carried out according to the operation. The time of the solder paste exposure to the air is as short as possible.

3, workshop humidity control

Monitor the humidity of workshop in a planned way, and control it between 40-60%.

4, set a reasonable furnace temperature curve

The furnace temperature is tested twice a day to optimize the furnace temperature curve, and the heating rate should not be too fast.

5, flux spraying

In the wave soldering, the spraying amount of flux can not be too much, spraying reasonable.

6. Optimize furnace temperature curve

The temperature of the preheating zone should meet the requirements, not too low, so that the flux can be fully volatile, and the speed of the furnace can not be too fast.

There may be a lot of factors affecting PCBA processing welding bubble, PCB design, furnace temperature, tin wave height, PCB humidity, chain speed, solder composition, flux (spray size) and other aspects to analyze, need to go through many debugging is likely to get a better process.