PCB Board Overview

Our company can process high-precision circuit boards with a minimum hole of 0.10mm, a minimum line width/spacing of 3mil, and a maximum number of layers of 30. The surface is gold, silver, copper, lead-tin, tin and other surface treatment processes. CEM-3, CEM-1, FR1, aluminum substrate, PTFE, ceramic and other rigid boards, as well as 1-8 layers of flexible circuit boards (FPC).

Our circuit board products are widely used in industrial controlling, electric power, national defense, medical, automotive, security, computer and other fields. With Soft-rigid combination board, etc., our company can process special processes such as thick copper windings, resin plug holes, stepped grooves, and countersunk holes, to meet personalized craftsmanship and quality requirements for our customers.

PCB process capabilities

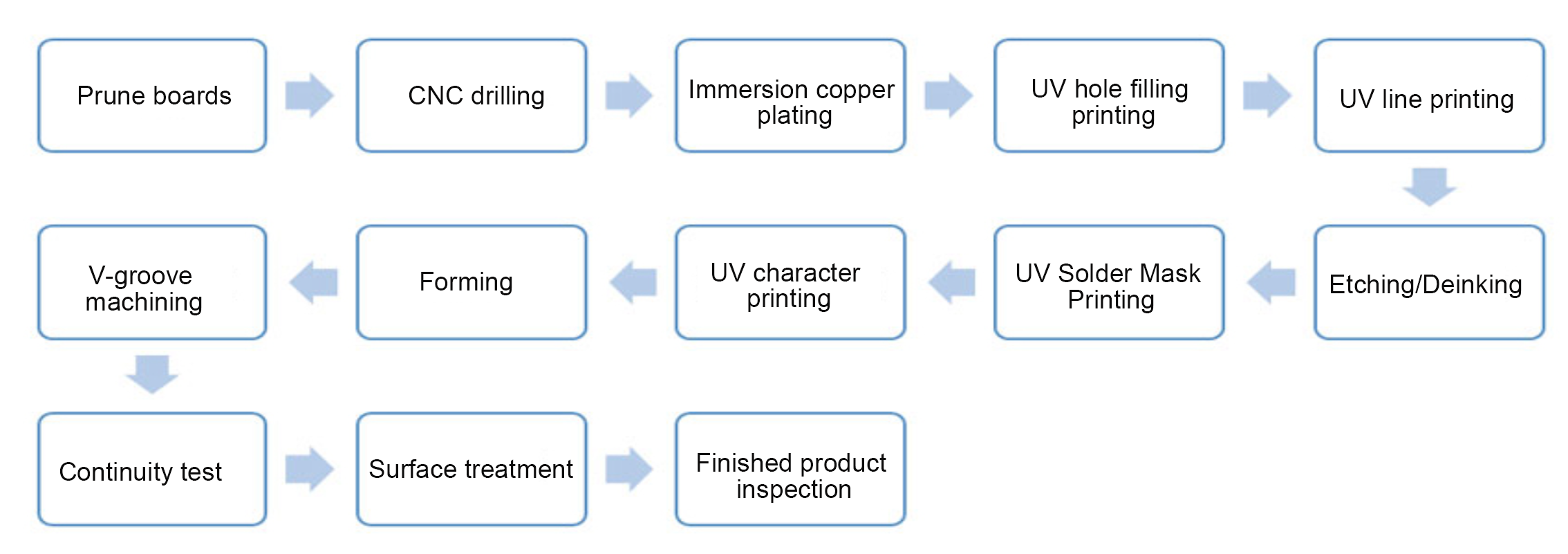

PCB production process

Production Process - Details Ensure The Quality Of Product.

Process*Drilling: Automatic detection of tool diameter, broken tool, post-drilling hole inspection, comprehensive elimination of slot skew and leakage, and guaranteed drilling accuracy.

Process * Copper immersion electroplating: Fully automatic copper immersion electroplating equipment, after multiple processes of tempering, the thickness of hole copper and surface copper far exceeds the industry standard.

Process* line: LDI laser exposure, direct line imaging, etching, demolding integrated production equipment (DES line), AOI optical inspection, to ensure line width and line spacing.

Process* Solder Mask: Fully automatic solder mask printing, baking in multi-temperature zones for more than 80 minutes, to ensure solder mask uniformity and adhesion, and comprehensively solve the risk of redness and copper leakage in the hole ring.

Process * Forming: The newly printed PCB board is a contiguous board. In order to meet the specifications and dimensions required by customers, the PCB board needs to be CNC edged or V-cut.

Process* test scanning: Automatic electrical test or flying probe test is used to eliminate all open circuit and short circuit problems, and ensure that each PCB board is a qualified product.

Online service

Service hours:9:00-18:00Telephone phone

135-1008-2025

0755-23501246

Pay attention to WeChat public account

Mail mailbox

ding@yctsz.com